Semiconductor shortage causing delays to lead times for new cars

Semiconductor shortage causing delays to lead times for new cars

The semiconductor chip shortage is impacting all vehicle manufacturers. In some cases, delivery times for new cars has extended from three months to six months. The situation isn’t much better for new vans, as many are not expected to be delivered until 2022.

When the coronavirus pandemic first took hold in early 2020, semiconductor manufacturers temporarily stopped their operations due to some companies reducing or cancelling their orders, having anticipated that there might be weaker consumer demand. Instead, the opposite occurred, as the global demand for semiconductors increased by 15%, due to massive demand from consumers to purchasing electronic devices such as computers and tablets so that they could keep themselves entertained throughout the various lockdowns.

Car manufacturers were among some companies that reduced semiconductor chip orders after car sales fell early in the Covid-19 pandemic, but this backfired after finding themselves at the back of the queue when they tried to reorder.

With the global manufacturing of semiconductors based on a handful of factories, the problem worsened because of power outages in Texas due to storms and a fire breaking out at a semiconductor facility in Japan.

What is a semiconductor chip?

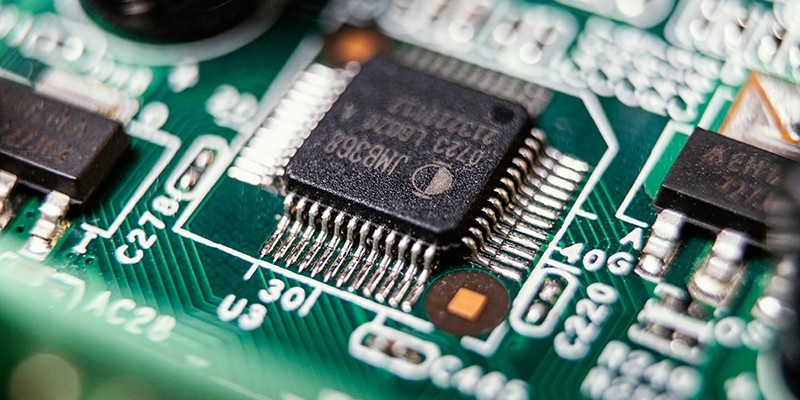

Semiconductors are mostly used to control electrical currents, and, within vehicles, the chips are used to control most electronic functions of key features such as battery management, brake sensors, parking cameras, infotainment systems and power steering.

Depending on the complexity of the new vehicle, there can be anything between 50 to 1,000 semiconductors used during the build.

What does this mean for the automotive industry?

The impact of the semiconductor shortage has also resulted in some car manufacturers reducing options on their vehicles. For instance, the Peugeot 308 is usually fitted with digital instruments but has now reverted to using analogue instead.

And on certain Citroen and Vauxhall models, the option for wireless phone charging is temporarily unavailable.

In addition, the Volkswagen Group, which is the parent company of VW, Skoda, Audi and the SEAT brands, confirmed that the shortage is contributing to “bottlenecks” in their production.

A spokesperson for Volkswagen confirmed the manufacturer had been working “successfully and intensely” to reduce the effects of the semiconductor shortage on their production. However, he said: “We currently assume that the supply of chips will continue to be strained in the coming months.”

Mercedes-Benz also said they are continuing to assess the situation in close coordination with their suppliers and suggested that deliveries of specific models could be affected.

Although there was a tenfold increase in car production within the UK in May, compared to the same month in 2020, new data from the Society of Motor Manufacturers and Traders shows that production is still down by 52.6% in contrast to the same month in 2019.

As demand for semiconductors continues to grow and exceed supply, Goldman Sachs estimates that the automotive industry is forecast to be one of the biggest losers this year, with up to £14 billion wiped off global car manufacturers’ operating profits.

How will this affect leasing a new car or van?

“It’s possible that global stock of semiconductors won’t return to pre-pandemic levels until 2022,” said Ash Jackson, Sales Manager at Fleet UK.

“It can take up to three to four months for a semiconductor chip to be produced. And what doesn’t help is that it takes a long while for semiconductor manufacturers to increase their output. Not only do they have to purchase and install the relevant tools, but you also have to factor in that it takes a couple of months to manufacturer the semiconductor chips well.”

“The shortage of semiconductors will have an impact on the delivery turnaround time for some new cars and vans.”

“However, the good news is that we can still source a wide variety of cars and vans from all manufacturers that are in stock.”

“If there is any expected delay to delivery times, we always keep the customer fully informed throughout the order process.”